Shutdowns for unexpected issues or even planned maintenance can be brutal to your operations. Even...

How Precision Maintenance Uncovered the True Culprits of Pump Failures

When a manufacturer acquired several struggling facilities, they quickly discovered a shocking truth: pump failures were rampant. With a dwindling maintenance staff, downtime skyrocketed, leading to decreased production. Clearly, a new maintenance plan was needed.

When a manufacturer acquired several struggling facilities, they quickly discovered a shocking truth: pump failures were rampant. With a dwindling maintenance staff, downtime skyrocketed, leading to decreased production. Clearly, a new maintenance plan was needed.

Don't miss the free resource at the end of the article!

The Cost of Cutting Corners

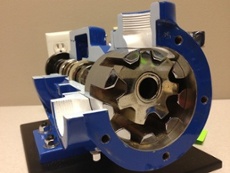

Before the acquisition, the facilities had been managed by an investment group focused solely on cheap production. Their tactic? Skimping on quality by using non-OEM replicated parts for their Goulds Pumps. The result? A surge in failures and downtime, costing the company tens of thousands of dollars in lost production and soaring energy bills. The upfront 25-30% savings on parts came at a steep price shortly down the road.

A Shift in Strategy

Upon taking over, new management recognized the disastrous domino effect of those cheap parts and initiated a Precision Maintenance program aimed at reducing unscheduled repairs. They invested in training their maintenance crew, emphasizing OEM specifications and tolerances when rebuilding pumps. It quickly became clear that the non-OEM parts were well beyond acceptable tolerances.

Their philosophy shifted from “buy the cheapest” to “invest in long-term value.” Leadership understood that smooth production lines, not cheap parts, generated revenue. Once genuine OEM parts were reintroduced into their Goulds Pumps, reliability surged. Seal failures decreased, and pumps operated longer between breakdowns.

A Broader Lesson

This isn’t just one isolated incident; many manufacturers are learning that prevention is both less disruptive and financially wiser. Preventing pump failures begins with proper installation and continues through diligent maintenance using the right parts.

Beware the siren song of sales pitches claiming replicated parts perform just as well as OEMs. Genuine OEM parts, coupled with a precision maintenance strategy, are key to your success.

>>> Download a FREE Predictive and Preventative Maintenance Checklist <<<

Curious About Your Costs?

Want to know what non-OEM parts are really costing you? Reach out! We assist businesses and municipalities in Michigan and Northwest Ohio in evaluating machine health and total cost of ownership.