The Essential Guide to Adhesives: From Raw Materials to Pump Selection

Adhesives are integral to countless everyday products—from cereal box closures to laminated furniture. With such a diverse range of adhesive applications, it's crucial to understand the various raw materials that make up these substances. Additionally, selecting the right pump for your adhesive depends heavily on its properties. In this guide, we’ll delve into the types of raw materials used in adhesives and how their characteristics influence pump selection.

Adhesives are integral to countless everyday products—from cereal box closures to laminated furniture. With such a diverse range of adhesive applications, it's crucial to understand the various raw materials that make up these substances. Additionally, selecting the right pump for your adhesive depends heavily on its properties. In this guide, we’ll delve into the types of raw materials used in adhesives and how their characteristics influence pump selection.

Types of Adhesive Materials

- Elastomeric Materials: These include adhesives made from neoprene, nitrile, and natural rubber. They are highly resistant to various liquids and excel in bonding fabrics and rubber products.

- Epoxy Resins: Known for their strong, durable bonds and excellent chemical resistance, epoxies are often chosen for demanding applications.

- Phenol Formaldehyde Resins: As one of the oldest synthetic resins used in adhesives, phenol formaldehyde resins are commonly used in plywood and veneer production.

- Polyvinyl Acetate: This versatile polymer adheres well to nearly any material and can be used with fillers like wood chips and clay for products such as ceiling tiles and wall boards.

- Sodium Silicate (Water Glass): This water-soluble silicate glass is popular for bonding paper and cardboard due to its low cost, minimal preparation needs, and nonflammable nature.

- Hot Melt Adhesives: Free of solvents, these adhesives become liquid when heated and bond surfaces as they cool.

Viscosity: Viscosity, the measure of a fluid’s resistance to flow, is a critical factor in pump selection. Lower viscosity fluids (thinner) flow more easily, while higher viscosity fluids (thicker) resist flow more. For instance, rubber cement has high viscosity, whereas polyvinyl acetates and sodium silicates are less viscous. Different pumps handle varying viscosities differently, so choosing the right pump is essential for efficient operation.

Corrosive Nature: The corrosiveness of an adhesive, determined by its pH level, can impact pump longevity. For instance, rubber cements, phenolics, epoxies, and sodium silicates are typically managed with iron or carbon steel pumps, while acid starches are better suited to bronze or stainless steel pumps. Polyvinyl acetates generally require stainless steel for durability.

Temperature: While not a property of the adhesive itself, temperature plays a crucial role in maintaining its pumpable state. Higher temperatures lower viscosity, making the adhesive easier to pump, while lower temperatures increase viscosity. It's important to manage the temperature to avoid issues such as adhesive hardening or clogging.

Stagnation and Hardening: Adhesives left stagnant can deteriorate or harden, causing potential system issues. Special care should be taken to avoid problems like "balling up" in mechanical seals, which can lead to seal leakage and failure. Rubber cement, for instance, has a tendency to ball up between mechanical seal faces, creating gaps and eventual seal failure.

Mechanical Seal Considerations: Mechanical seals can generate heat, which might exacerbate adhesive issues. Proper selection and maintenance of seals are essential to avoid problems related to material degradation and system inefficiencies.

Selecting the right pump for adhesive applications requires a thorough understanding of the adhesive’s raw materials and properties. By considering viscosity, corrosiveness, temperature, and the potential for deterioration, you can better ensure that your pumping system operates smoothly and efficiently. What other factors do you consider when choosing a pump for adhesives?

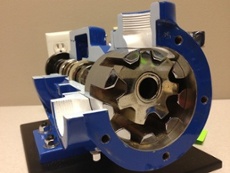

Professional Pump, located in Belleville, Michigan and serving businesses throughout Michigan and NW Ohio, represents the best brands in the industry, including the Gorman-Rupp Gear Pump, perfect for your adhesive applications. You can read more about selecting a gear pump on our blog, "Top 9 Factors to Consider Before Selecting a Gear Pump."

Professional Pump, located in Belleville, Michigan and serving businesses throughout Michigan and NW Ohio, represents the best brands in the industry, including the Gorman-Rupp Gear Pump, perfect for your adhesive applications. You can read more about selecting a gear pump on our blog, "Top 9 Factors to Consider Before Selecting a Gear Pump."

We also carry valves, mechanical seals, filters, mixers, tanks, couplings, and more. Contact us today to get started with your pump selection or repair.

Click to access our free eBook, The Engineer's Guide to Pumping Adhesives: