Water hammer is one of the most disruptive and expensive problems in industrial fluid systems—yet it’s also one of the most preventable. At...

The Slip-Up: Why Lower Viscosity Can Lead to Less Flow in Gear Pumps

.webp?width=453&height=419&name=gear-pump-slip%20(1).webp)

Recently, one of our engineers quoted a replacement gear pump, and the customer was puzzled by the flow rates. Our engineer had listed the pump's flow at 107 GPM at 22 cps and 114 GPM at 25,000 cps. Could it really deliver more flow with higher viscosity? Spoiler alert: it can! Let’s dive into why that’s the case.

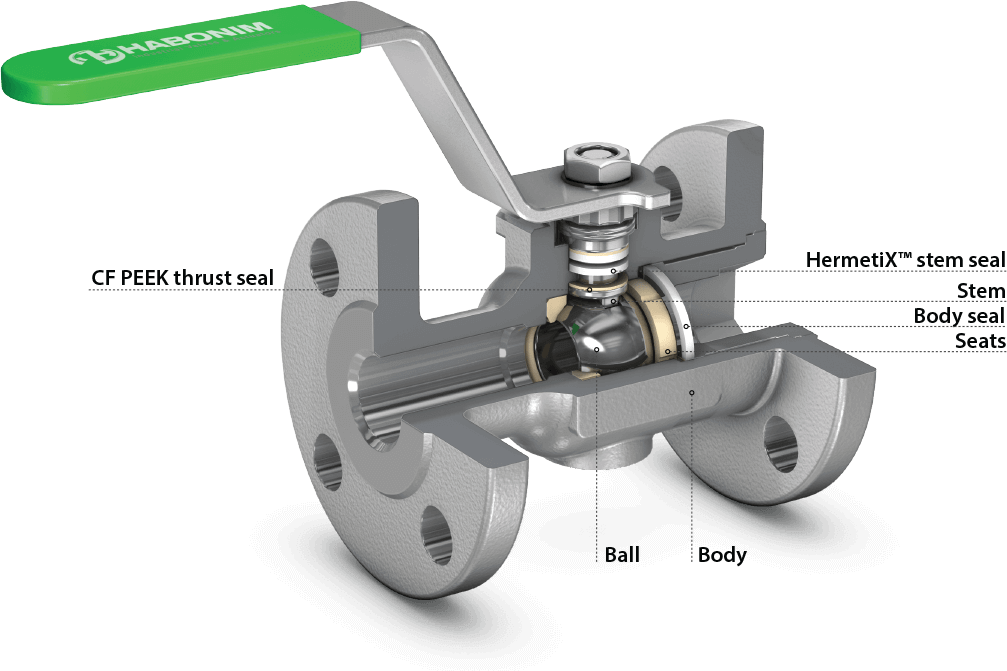

Gear pumps thrive in high-viscosity applications, but when viscosity drops, slip becomes a problem. Slip occurs when fluid recirculates from the discharge back to the suction side, sneaking through machined clearances while the pump struggles to push it forward. While not typically a showstopper, slip can lead to frustrating issues, especially with tricky fluids like chocolate and adhesives.

This illustration shows how slip travels backwards through a gear pump.

The degree of slip hinges on both fluid viscosity and discharge pressure. Thin fluids glide through clearances more easily than thicker ones. Plus, high discharge pressure can force those lighter fluids back through the pump, exacerbating slip.

In short, when thin fluids slip, the pump’s efficiency plummets, resulting in a lower flow rate.

To maximize your gear pump’s performance, ensure it’s properly sized for your application, clearances are adjusted for the fluid’s viscosity, and discharge pressure is kept low to prevent backflow.

Consult with a Fluid Handling Expert

Think your gear pump could use a tune-up? Reach out! We’re here to provide expert assistance to businesses and municipalities in Michigan and northwest Ohio.